Track-Pipe® | Stainless Steel | 4000mm

Track-Pipe® | Stainless Steel | 4000mm

Couldn't load pickup availability

Technical Specification

Technical Specification

- Supply Voltage: 48 V DC

- Primary Material: Stainless Steel

- Finish: Stainless Steel

- Weight: 2.3kg/m

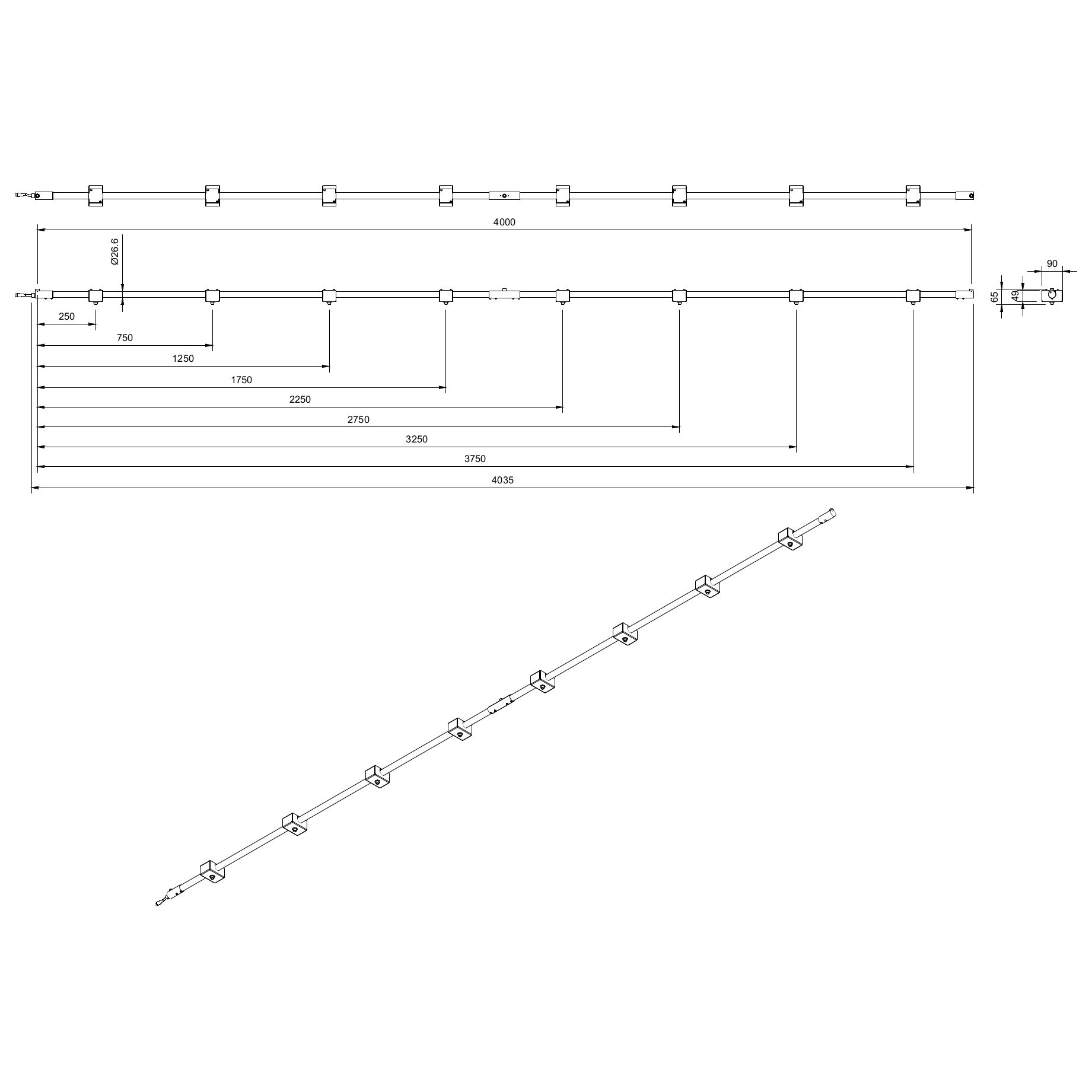

- Mounting: Wire Suspension | M10 Threaded Rod | Other M10 Fixings

- IP Rating: IP20

- Current (mA max.): 6A Max

- Power Consumption (max. typ.): 288 W Max

- Operating Temp: Ambient -20°C/+25°C

- Control: Switched, DALI

- Standard/Certification: CE | UKCA [BS EN 60598] | USA/Canada: Manufactured in line with UL2108

- Manufacture: UK

Description

Description

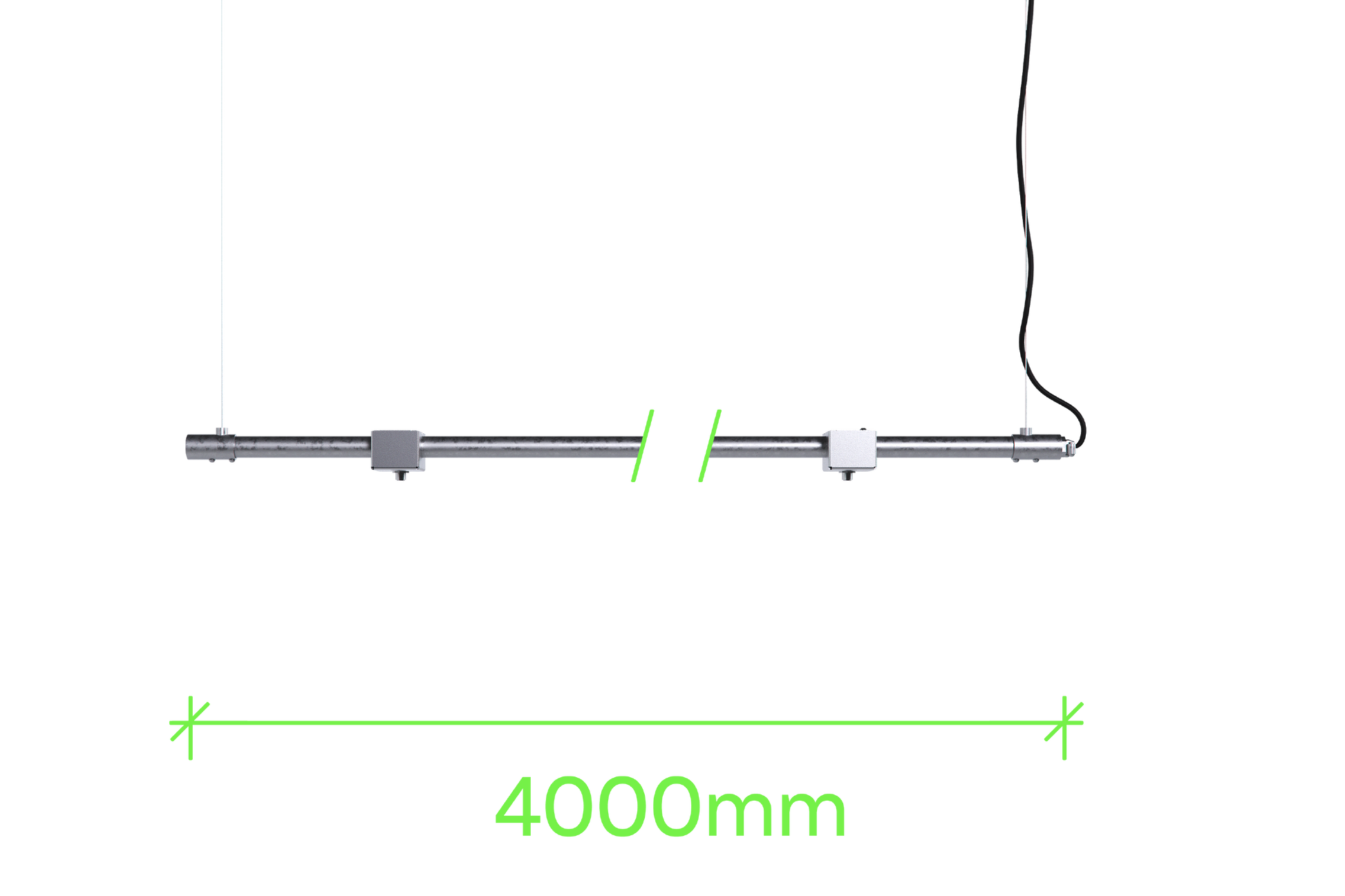

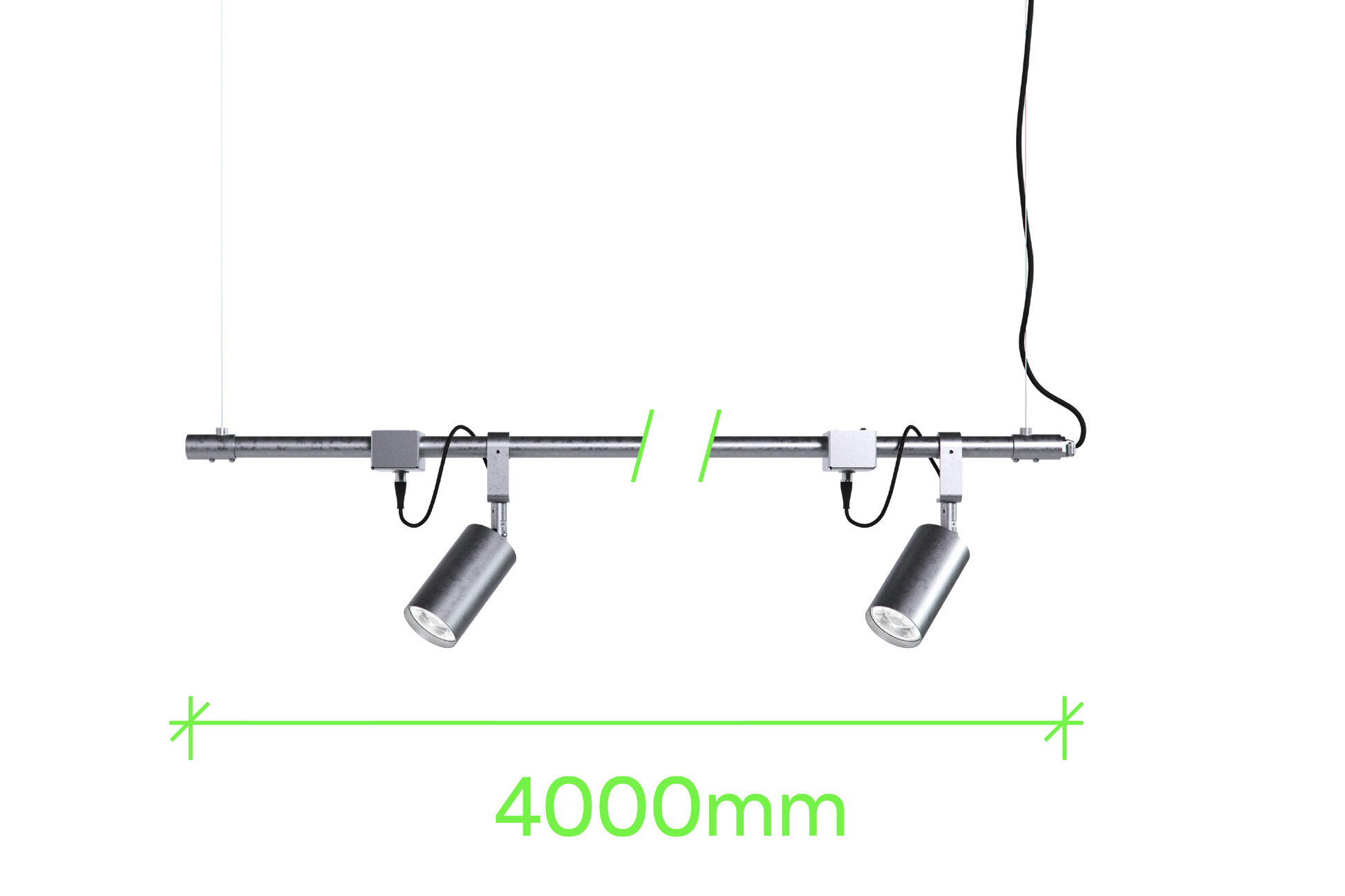

This lighting track system does the same job as regular lighting track, but without the plastics, paint and adhesives.

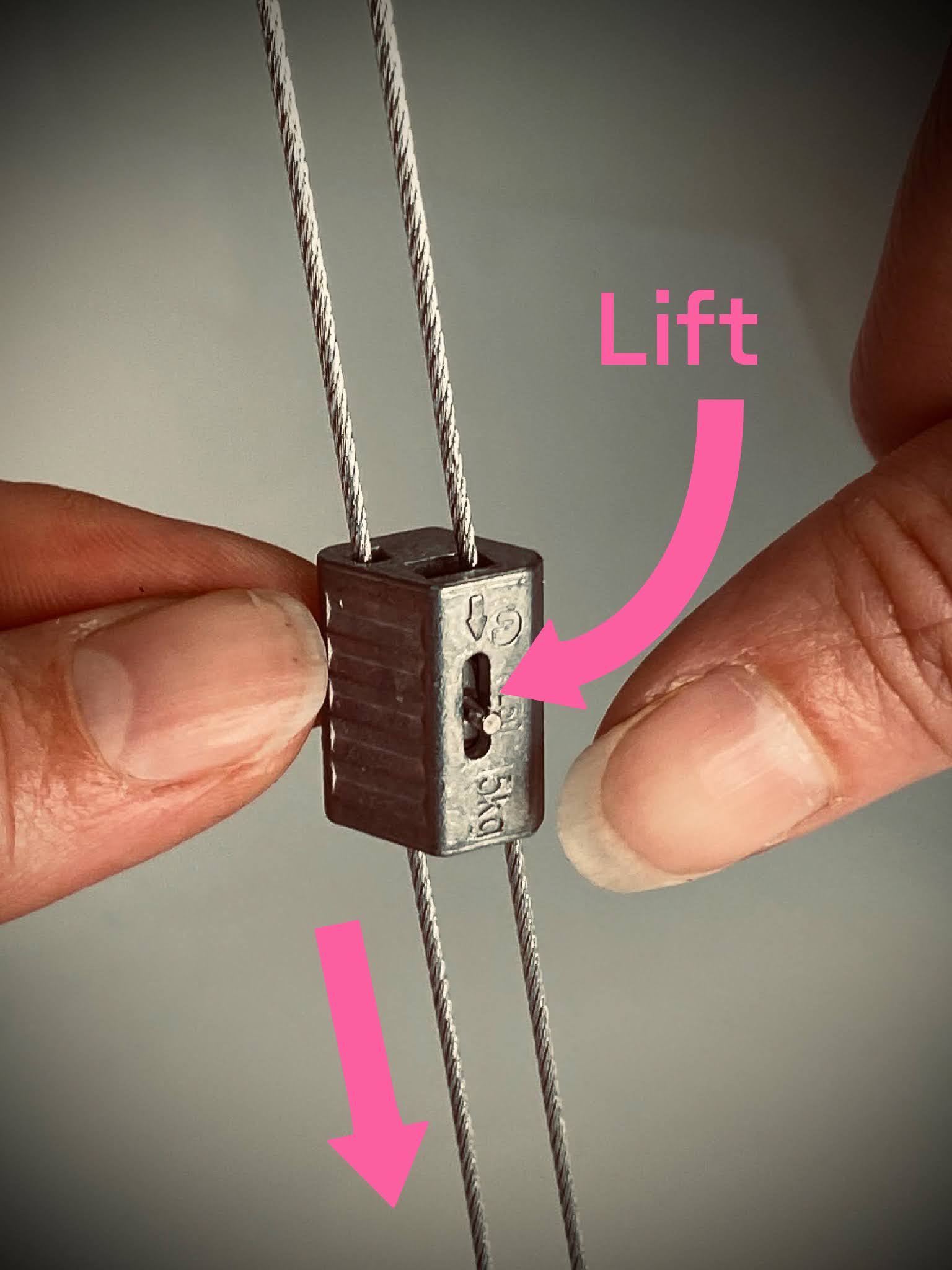

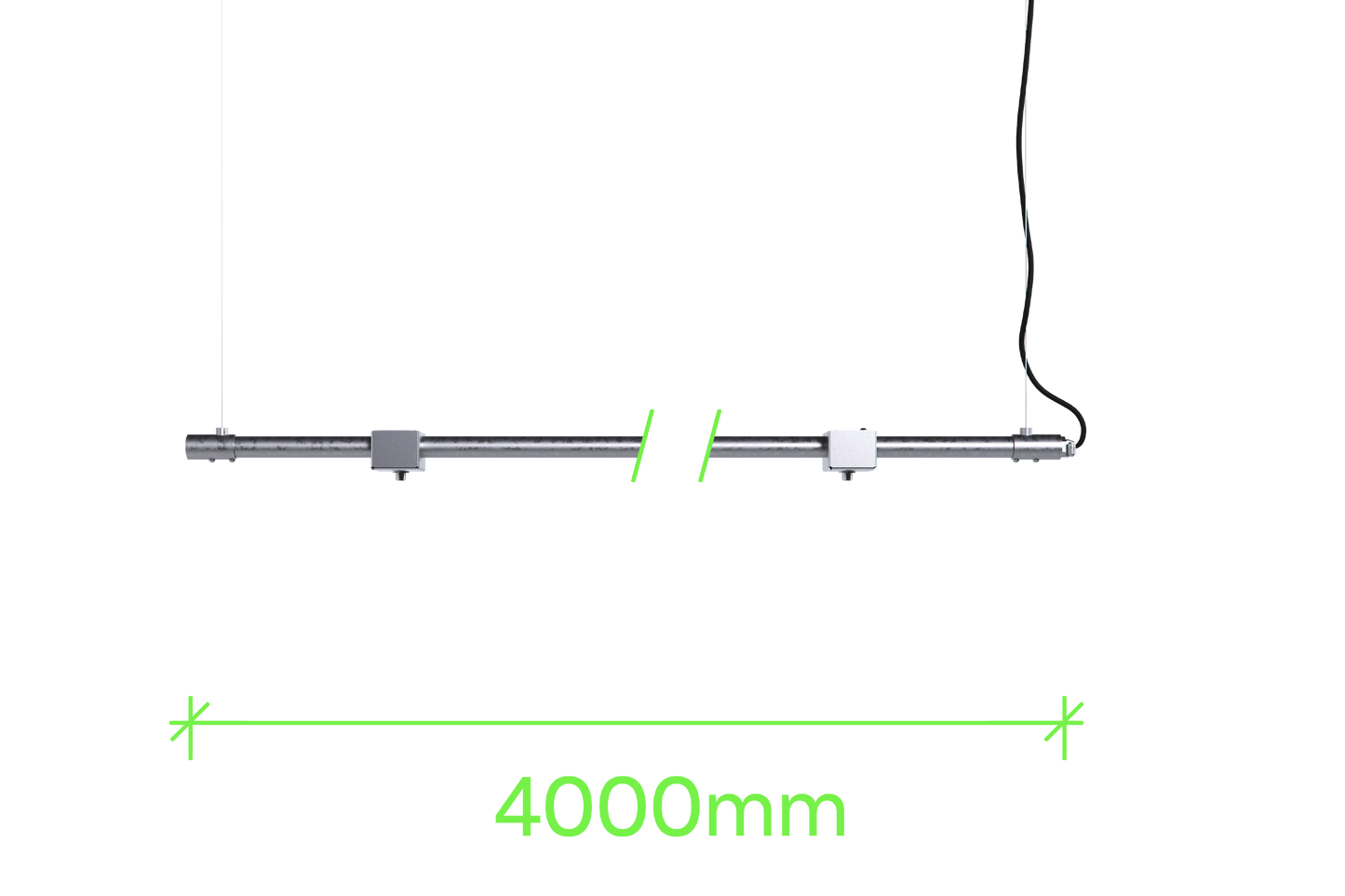

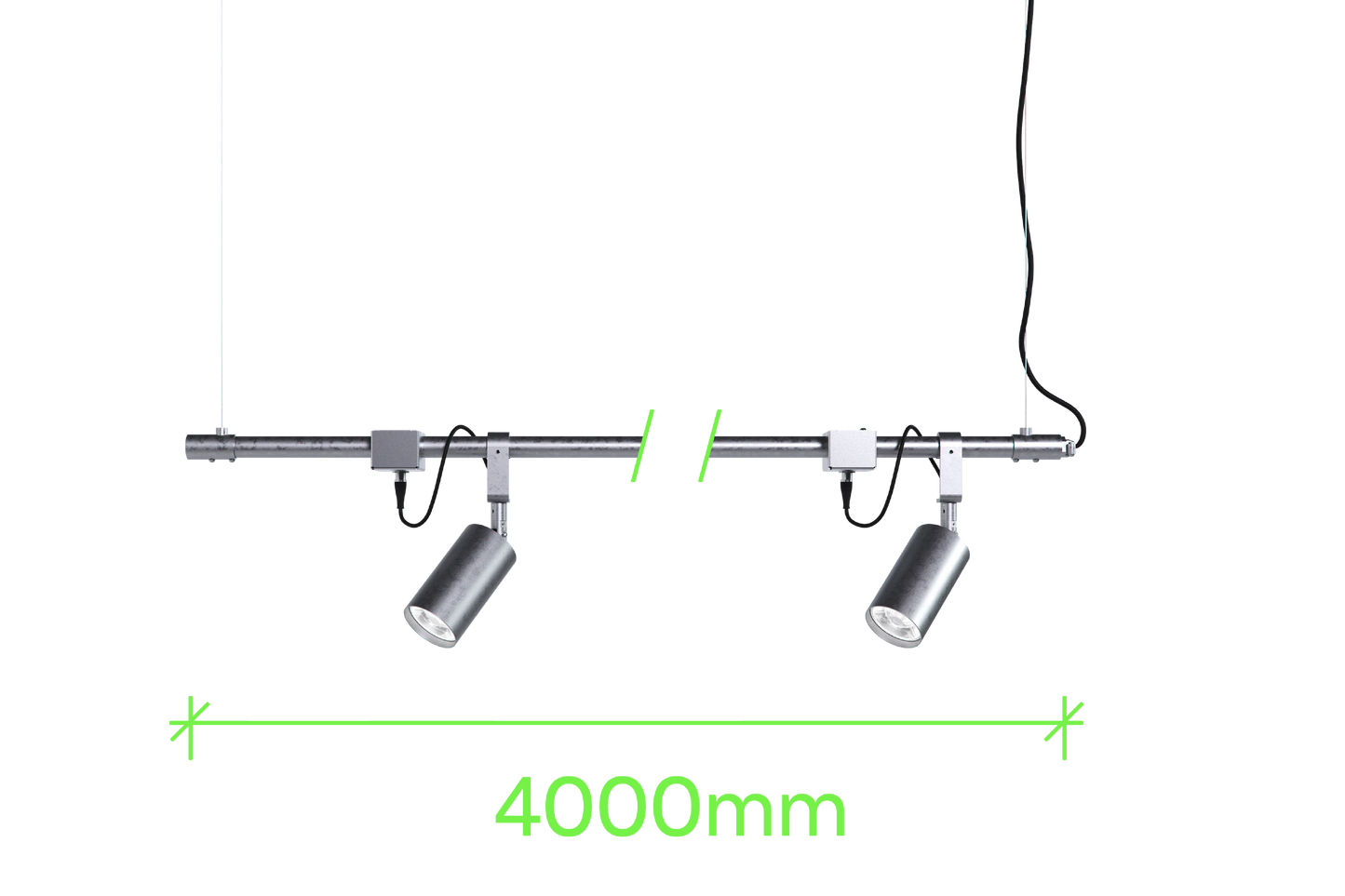

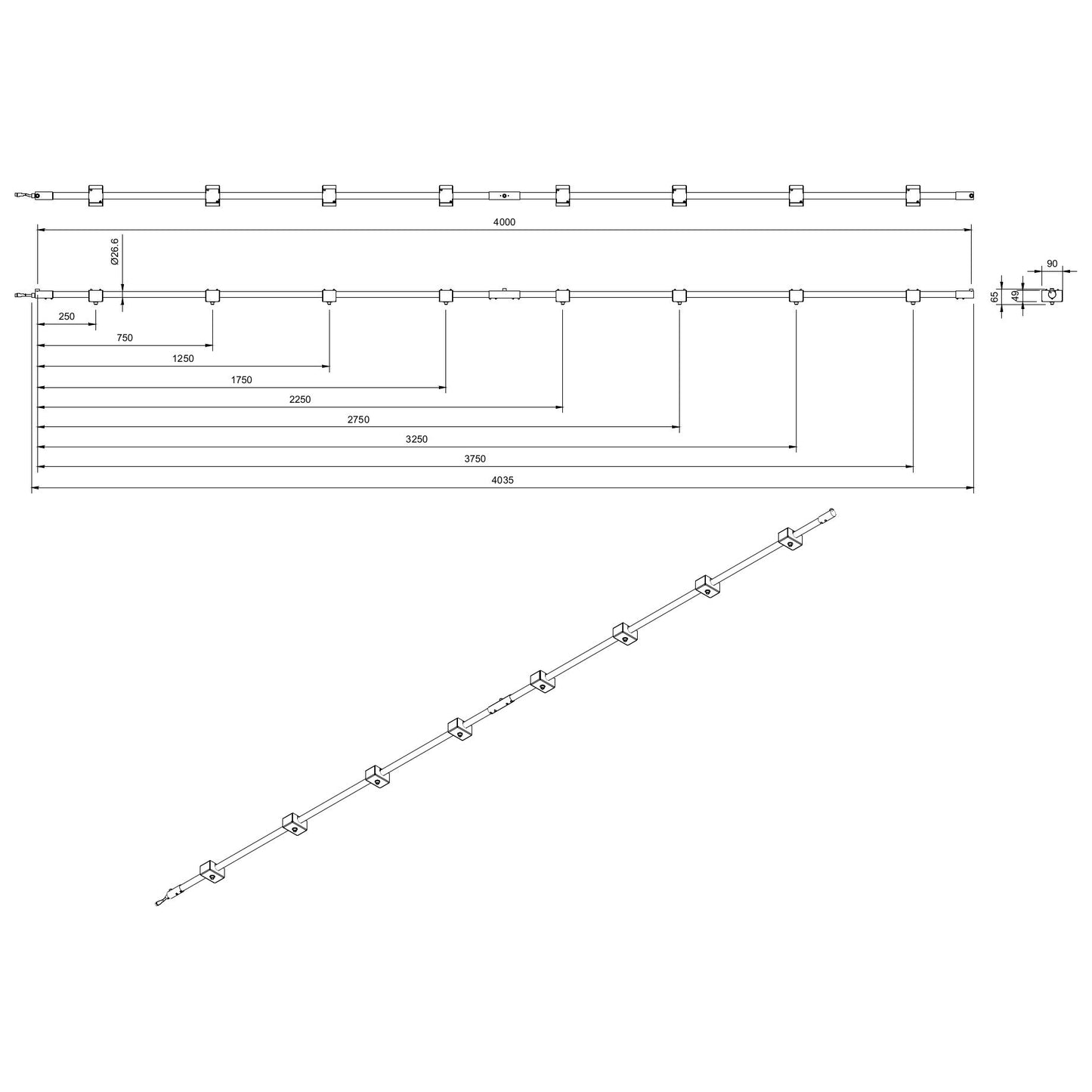

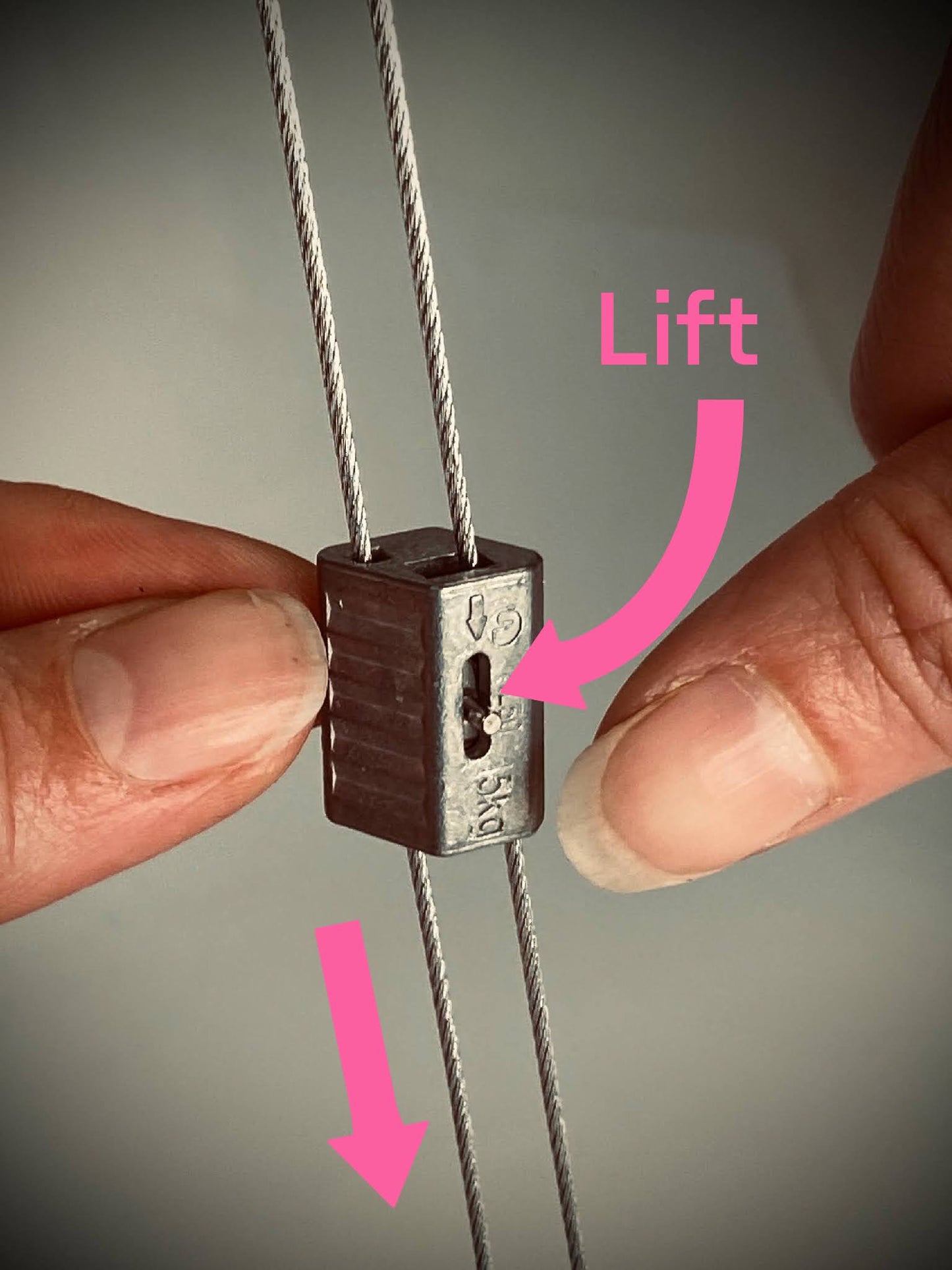

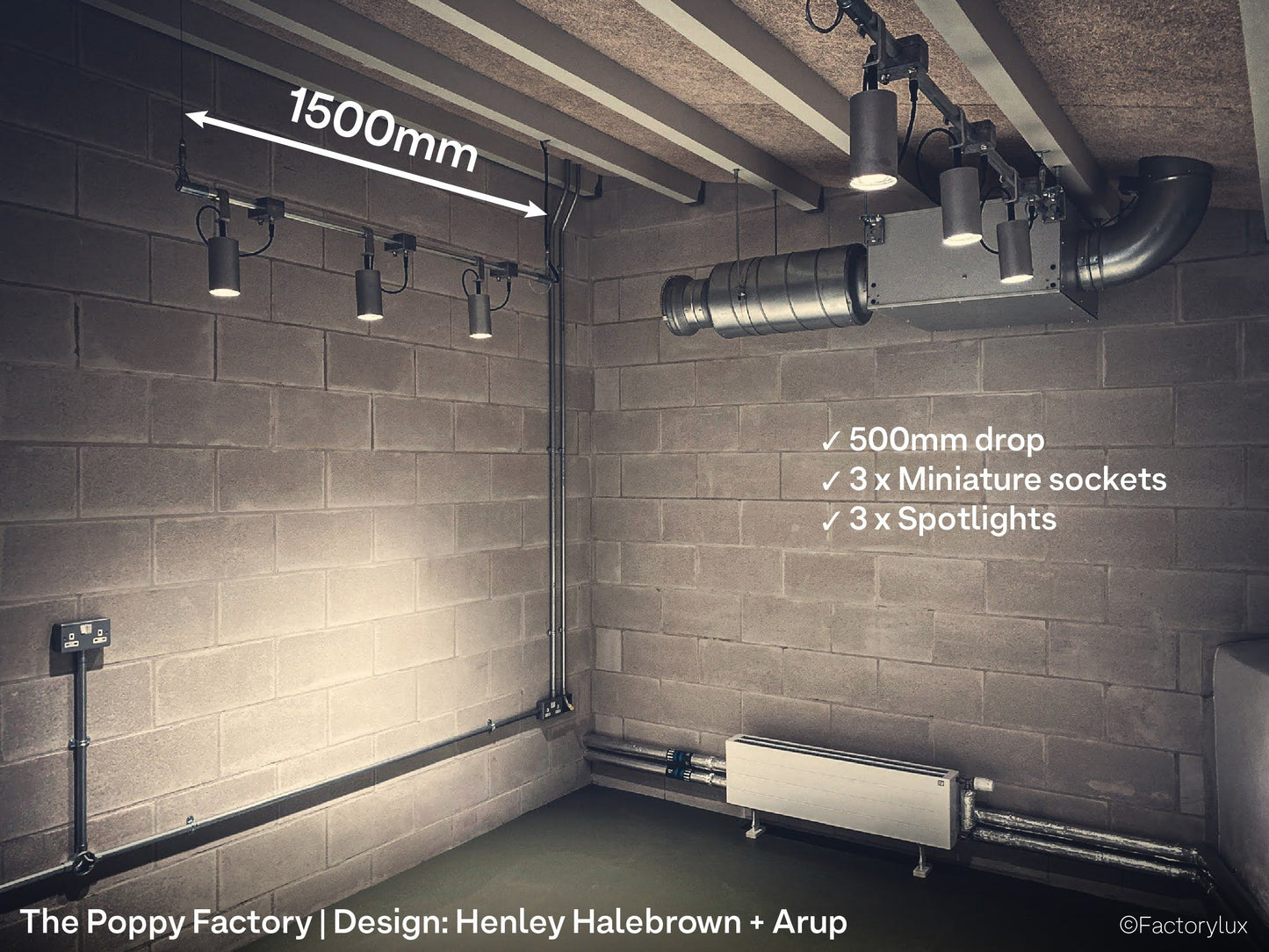

Track-Pipe® is simple to specify and fast to install. The tube is made from high-strength / high-stiffness 304 stainless steel, each extra 3000mm of horizontal tube requires just a single 1mm vertical stainless steel suspension wire. One power and data connection can feed a single run from 1,000mm to 10,000mm long, with up to 20 individual spotlights. Compatible spotlights are easy and safe to reposition anywhere along the tube.

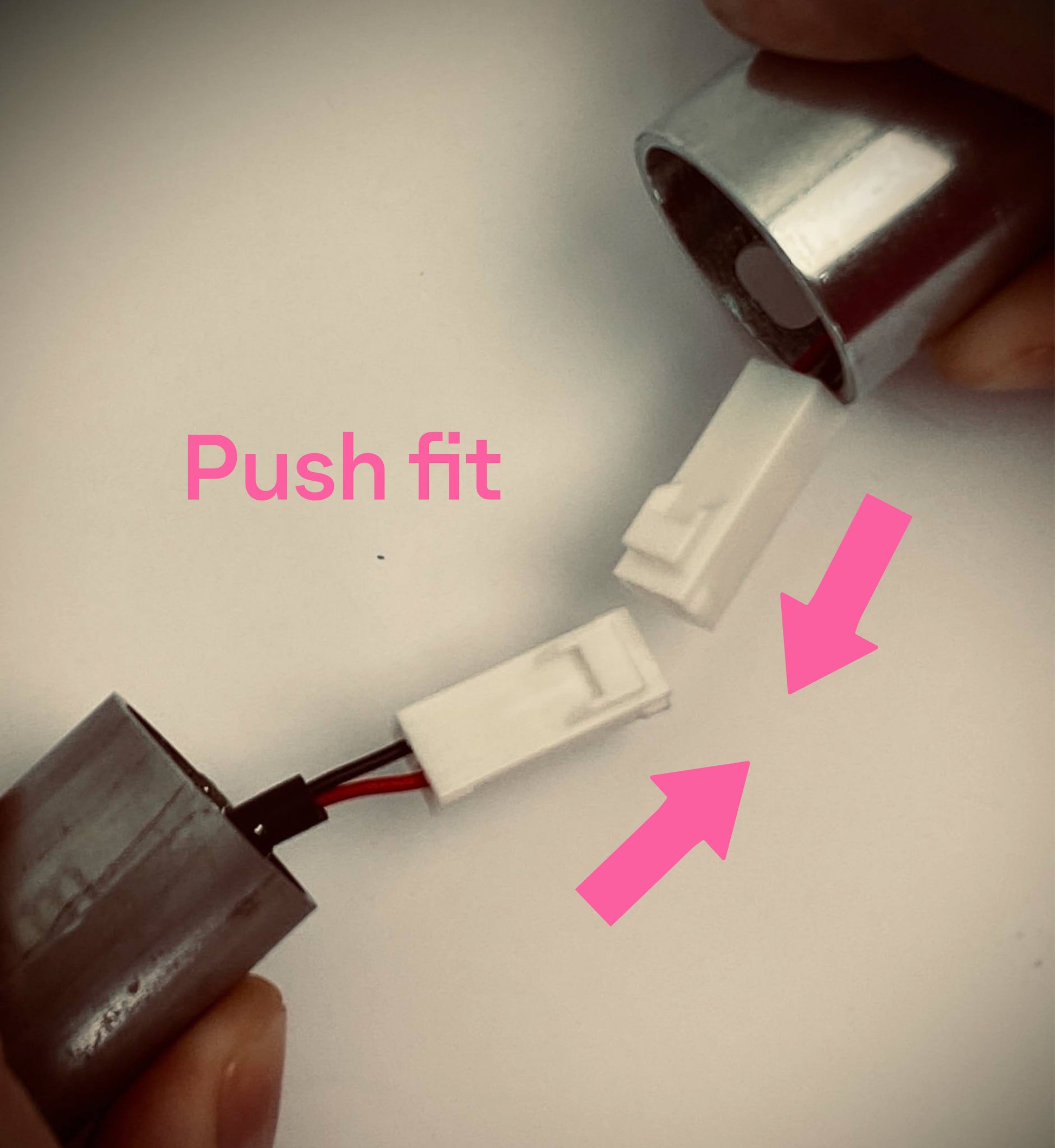

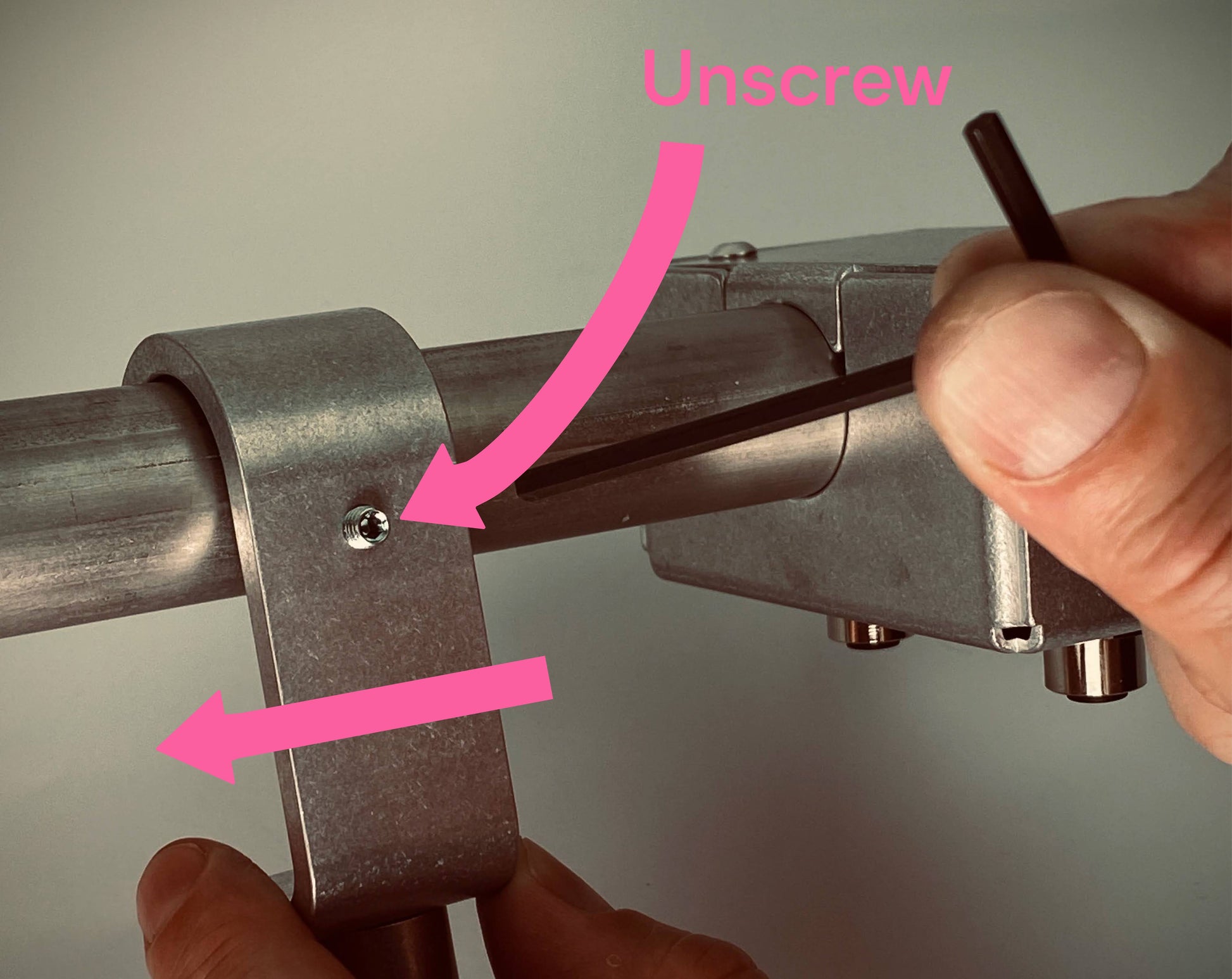

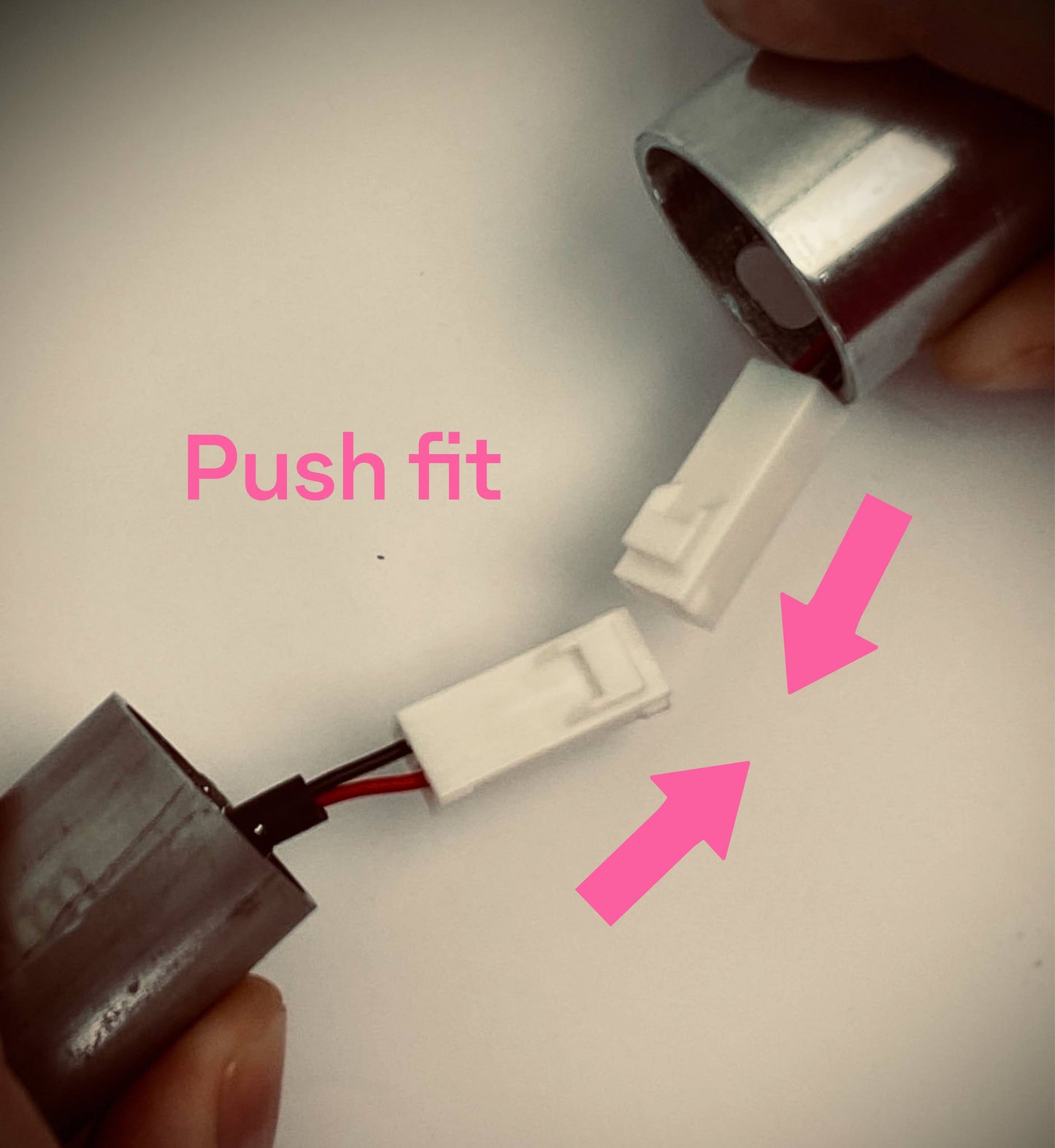

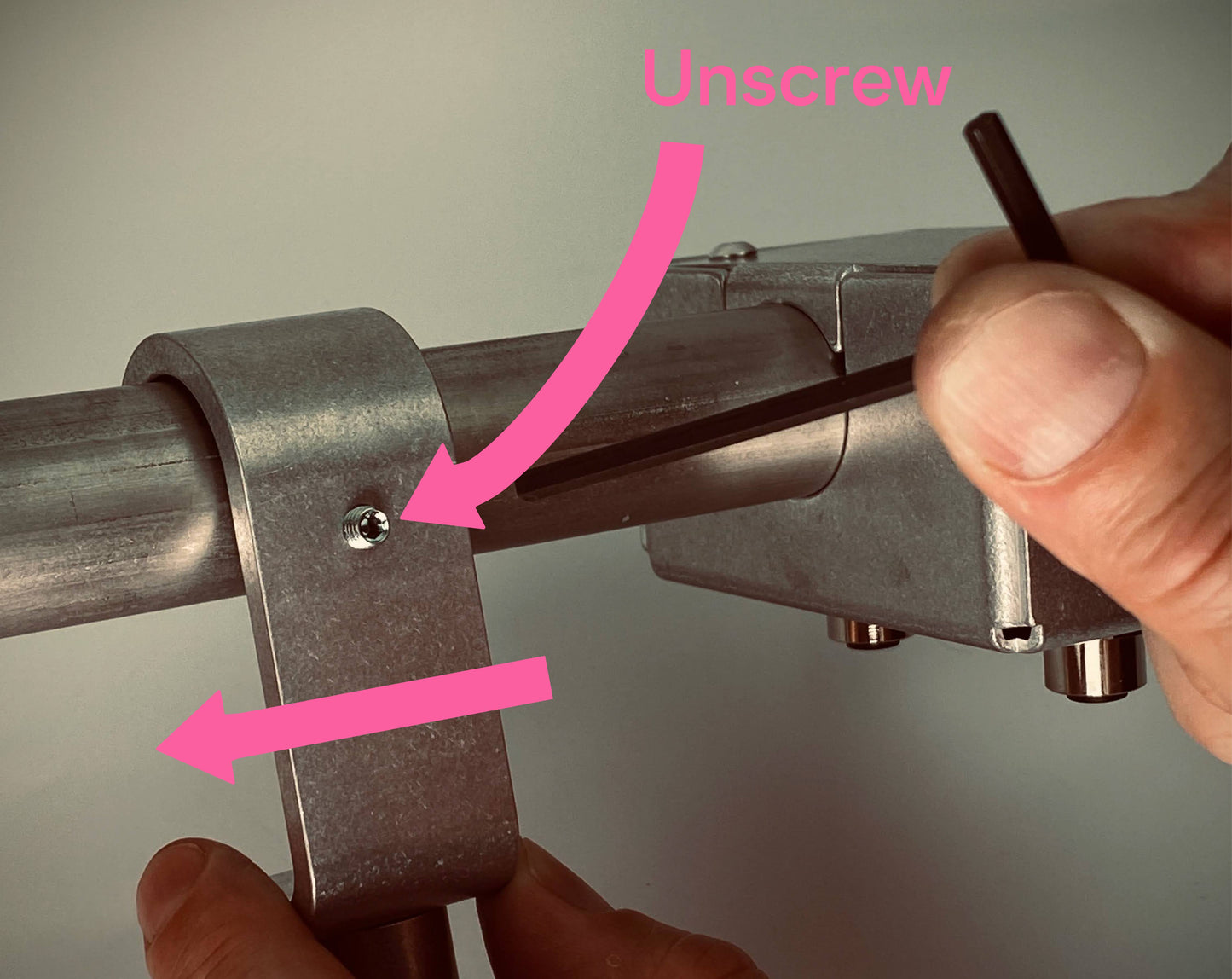

Supplied in straight runs of 1000mm to 10,000mm length, with a single 2000mm long cable to connect your power and data. No on-site measuring, cutting or time-consuming assembly work is required. Runs over 3000mm are supplied in separate pieces that join together with a robust stainless steel coupler and push fit connector for power and data.

Best of all, there's no paint or other surface coatings (it's lightly sanded for a consistent, matte texture) which means our factory can reprocess 'used' Track-Pipe® into 'new' components again & again with minimal energy and zero pollution. From a Life Cycle Assessment point of view, Track-Pipe® is a solid ecological choice and can score points on environmental / well-being assessments such as BREEAM, LEED, WELL, SKA.

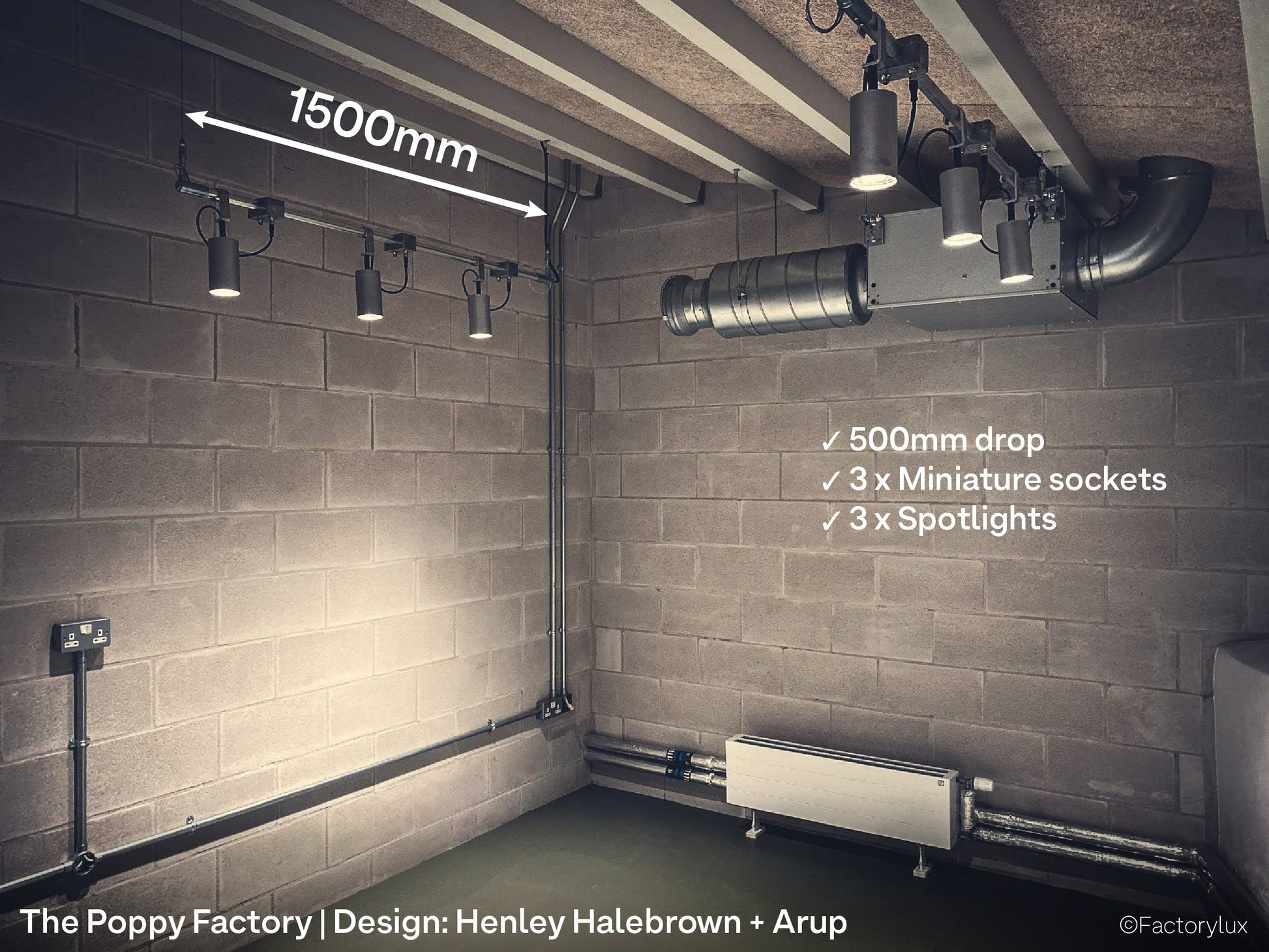

In Summary: From multi-national 'Big Tech' corporations such as Google, to local 'Real Food' start-ups such as Atis - architects, designers and building engineers all over the world came for sustainable development goals, but stayed for the clean lines.

Body:

- 100% free-from paint, plastic & adhesives

- No microplastic pollution

- No Isocyanates or VOC (volatile organic compound) off-gassing

- Repair, upgrade or disassemble with standard tools

Electronics:

- Long-life, replaceable AC/DC Power Supply

- PVC-free cables

Closed Loop Circular Economy:

- Make-Unmake™: our factory can disassemble 'used' Stone-Rumbled™ body components and 're-rumble' back to 'new' again (and again)

- Magic-Packaging™: 100% paper - every product, every project (even the pallets and strapping) definitely no plastics

- 100% Designed & assembled in Yorkshire

- Component origins include UK, EU, Mexico, Taiwan, China & Phillipines

All Track-Pipe® is designed and assembled in Yorkshire.

Our team deliver sustainable lighting at prices your project can afford.

No sale reps. No agents. No hidden commission.

Our modern, digital-first workflow is simple not salesy. It can deliver big cost savings for your project.